Inventory Control

Inventory control is a process that involves gaining greater oversight of the stock of a company. Some people consider it as an internal control or an accounting system that is established to protect significant assets of a company. Your company can also depend on such systems to do Inventory control, to evaluate your present assets, offer financial reporting and balancing your accounts.

Importance of Inventory Control

No business would want to lose their sale just because of failing to have an adequate inventory in place to fulfil the order. Inventory issues like frequent backorders can result in driving customers to look for other suppliers. With a proper control over inventory, an organisation can offer improved customer service.

Excess inventory can also lead to trouble. It would take up a lot of space unnecessarily in the warehouse. This excess inventory can cause profit losses when a product gets broken, expires, or becomes out of season. The right understanding of the demand of customer for the company’s product is the key to ensure better inventory control.

Inventory control is a must for maintaining the correct balance of stock in the warehouse. It helps a business to understand what they have, where is it present in the warehouse, and the time when the stock is moving in and out of the organisation. This action can result in reducing costs, increases fulfilment, and eliminate fraud.

Ways that a company adapt to control Inventory

Manual procedure

There are two main ways by which an organisation can manage their inventory. One of them is the manual process wherein a spreadsheet with several different columns is created. Each of these columns shows a different description of the product such as product name, product code, quantity etc. This spreadsheet will help in keeping track of new incoming stock and returns.

Managing this spreadsheet is quite apparent a cumbersome and time-consuming task that no expanding business wishes to deal with. Continuous monitoring in this way for every transaction is not an easy task. Not just information sharing becomes difficult, but also there is a lot of possibility of resulting in a human error. Inaccurate inventory number is a common problem with this approach which is solved with the introduction of automated processes.

Automated process

The more automated a system gets, lesser will be the paperwork. You may find several different inventory control software systems that offer integration with the multichannel integrations or enterprise resource planning structures.

Ways by which inventory portfolio can be upgraded to gain maximum long-term returns:

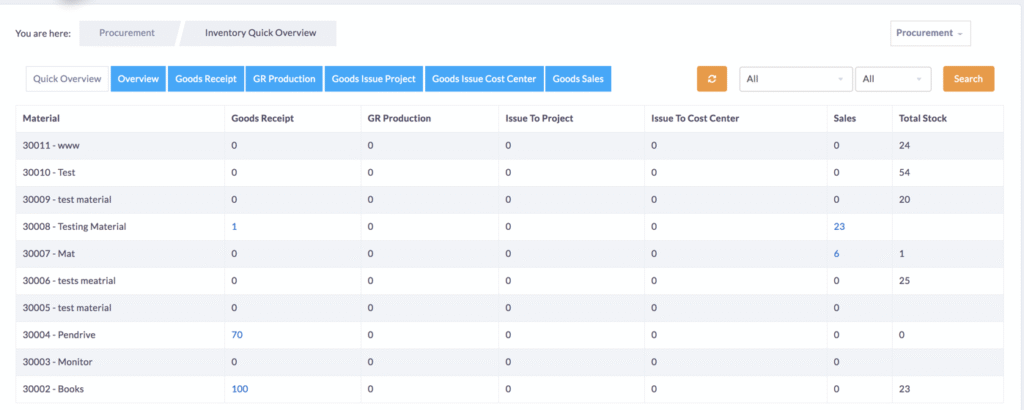

- Tracking items across different locations for quick and constant updates

- Streamline check-ins and check-outs of inventory for efficient project distribution

- Eliminate outages via automated stock management

- Make provision to accommodate diversification

- Record product usage over time to estimate demand

- Refine inventory management practices using inventory control software

CONCLUSION

Inventory control is significant for the survival of the business. Don’t let shortages or excess of inventory to become the downfall of your business. The method you choose will depend on your business type and the essential features that need to be fulfilled. You can use software applications like ONEBUSINESS to have better control of the Inventory.