Streamlining Manufacturing with OneBusiness ERP: A Deep Dive into the Production Module

ERP production software :In today’s fast-paced manufacturing landscape, agility, traceability, and precision are no longer optional—they’re essential. The OneBusiness ERP Production Module is designed to meet these demands head-on, offering a unified platform that integrates planning, execution, and cost control across the entire production lifecycle. Whether you’re managing a tea factory, a garment unit, or a rubber processing line, OneBusiness ERP brings structure and intelligence to your shop floor.

Modular Design for Real-World Complexity

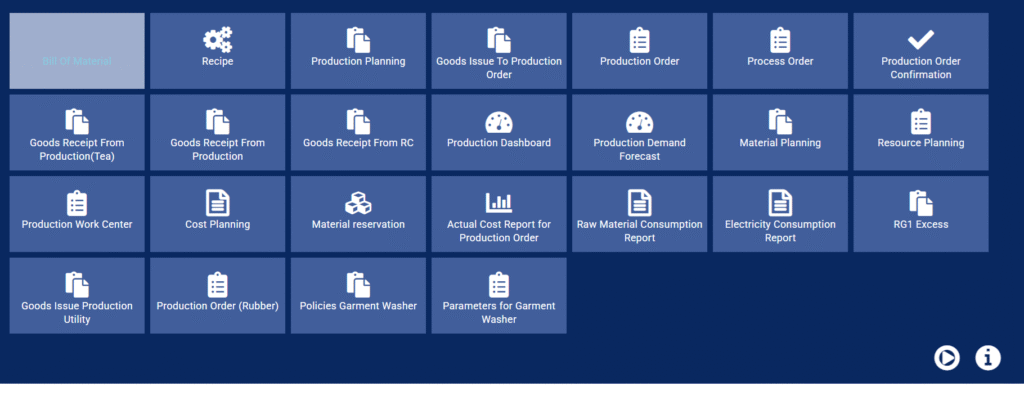

The Production Module in OneBusiness ERP isn’t just a single screen—it’s a comprehensive suite of interconnected functionalities. From Production Planning and Material Reservation to Goods Receipt and Actual Cost Reporting, each tile in the interface represents a critical step in the manufacturing journey.

Key modules include:

• Production Order & Process Order: Create and manage discrete or process-based production workflows.

• Production Planning & Demand Forecast: Align production schedules with real-time demand signals.

• Material & Resource Planning: Optimize raw material availability and machine utilization.

• Production Dashboard: Visualize KPIs, bottlenecks, and throughput in one glance.

This modularity allows manufacturers to tailor the system to their specific industry needs—whether it’s batch processing in food production or continuous flow in textiles.

Seamless Integration Across Operations

OneBusiness ERP doesn’t operate in silos. The Production Module is tightly integrated with:

• Inventory Management: Real-time stock updates via Goods Issue and Goods Receipt transactions.

• Finance Module: Automatic posting of production costs and variances.

• Quality Control: Embedded checkpoints for compliance and defect tracking.

• Utilities Tracking: Monitor electricity and water consumption per production order.

This cross-functional integration ensures that every production decision is backed by accurate data—from raw material availability to cost implications.

Real-Time Visibility and Control

The Production Dashboard and Work Center Management features empower supervisors and plant managers with real-time insights.

You can monitor:

• Order status and completion rates

• Machine-wise performance

• Operator efficiency

• Utility consumption trends

For example, the Electricity Consumption Report helps correlate energy usage with output, enabling sustainability initiatives and cost-saving measures.

AI/ML-Enhanced Forecasting and Costing

OneBusiness ERP goes beyond traditional ERP logic by incorporating AI/ML models into its forecasting and costing engines. The Production Demand Forecast module uses historical data and seasonal trends to predict future requirements. Meanwhile, the Actual Cost Report for Production Order compares planned vs. actual costs, flagging anomalies and inefficiencies.

This predictive capability is especially valuable for industries with volatile input costs or fluctuating demand cycles.

Whether you’re producing tea, rubber, garments, or chemicals, OneBusiness ERP adapts to your terminology and workflows. Specialized modules like:

• Goods Receipt from Production (Tea)

• Production Order (Rubber)

• Policies and Parameters for Garment Washer

ensure that your ERP system speaks your language. This reduces training time and improves user adoption across departments.

Compliance and Reporting Made Easy

Regulatory compliance is built into the DNA of the Production Module. Features like:

• RG1 Excess Reporting

• Raw Material Consumption Reports

• Cost Planning and Variance Analysis

help manufacturers stay audit-ready and transparent. Reports are exportable and customizable, making it easy to share insights with stakeholders or regulatory bodies.

Why OneBusiness ERP Stands Out

Unlike generic ERP platforms, OneBusiness ERP is built with manufacturing nuances in mind. Its intuitive UI, modular architecture, and AI-enhanced features make it a powerful ally for production managers, CFOs, and IT teams alike.

Whether you’re scaling operations, optimizing costs, or digitizing legacy workflows, the Production Module offers a future-ready foundation for smart manufacturi