OneBusiness ERP Production Planning

BEST ERP PRODUCTION PLANNING SOFTWARE

Manufacturing ERP denotes an enterprise resource planning (ERP) system and software crafted to oversee, strategize, and execute vital operational functions that bolster the business operations of manufacturing firms. These Manufacturing Management functionalities encompass production planning, inventory control, production scheduling, recipe planning, resource planning, and raw material planning and execution. OneBusiness streamlines this intricate process by offering a concise cost of production calculation sheet, allowing for a swift overview of production status. Integrating OneBusiness manufacturing ERP applications seamlessly fits into an organization’s pre-existing business processes, presenting a comprehensive business management solution applicable across diverse manufacturing industries. Notably advantageous for generic production industries, the Manufacturing Management module is also tailored to meet the specific processes of tea factories within the OneBusiness ERP system. Furthermore, the flexibility of customization within the production planning module enables swift adaptation to specific requirements with minimal effort, ensuring adaptability to unique manufacturing needs.

.

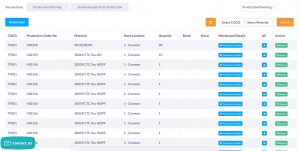

- OneBusiness ERP Production Planning Production order allows for the planning and execution of production processes in a manufacturing environment.

- ERP Production management software or production scheduling software plays a significant part in any Manufacturing Industry. Planning your production with an order provides the following benefits:

- Understanding of resource requirements and availability

- Raw material position and automatic purchasing

- Production capacity assessment

- The average duration of an order

- Cost of production of a product in real-time

Utility consumption trends and corrections

- OneBusiness Production management software can track day-to-day production progress on completing any work order. In addition, reports will be available in this module.

- Production planning software helps an organization plan production, planning with the best use of all available resources.

- Maintaining a smooth workflow improves the work environment due to reduced labour and production costs.

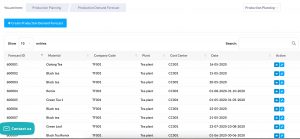

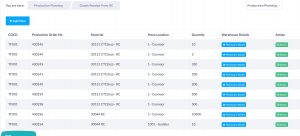

ERP Production Planning Software Dashboard:

The Production planning dashboard gives you a quick overview of every product’s production, sales, and stock.

This report consolidates the view by week, month and year.

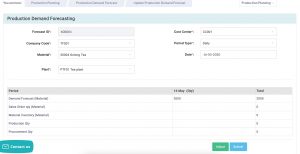

This transaction is a planning platform for your primary production of various products. You can obtain the forecast figures from an external source or your past historical records.

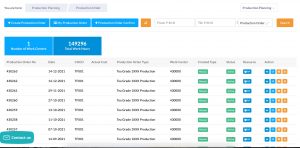

Production Planning Process

The production planning transaction will adopt the planning values from your production forecast. In addition, you can change the forecast values before automatically creating the production order.

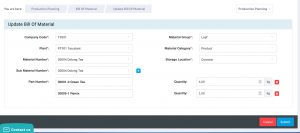

Material Planning

Material requirements planning (MRP) is a process by which a system calculates the materials and components requirements to manufacture a particular product.

It consists of the following essential steps:

1. Bill of Material, which will encompass the primary raw materials for the product

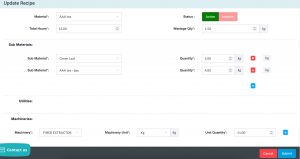

2. Recipe for a product will cover the utility and other requirements for the production process

3. Production order material and planned quantity as a starting point for the material planning

4. Stock item or a non-stock item based on the company policy and the delivery timeline of the product

5. Create a reservation or a purchase requisition for the requirements quantity.

OneBusiness Production planning will perform all of the above tasks automatically with minimal input from the user.

Material requirements planning (MRP) is a process by which a system calculates the materials and components requirements to manufacture a particular product.

It consists of the following essential steps:

1. Bill of Material, which will encompass the primary raw materials for the product

2. Recipe for a product will cover the utility and other requirements for the production process

3. Production order material and planned quantity as a starting point for the material planning

4. Stock item or a non-stock item based on the company policy and the delivery timeline of the product

5. Create a reservation or a purchase requisition for the requirements quantity.

OneBusiness Production planning will perform all of the above tasks automatically with minimal input from the user.

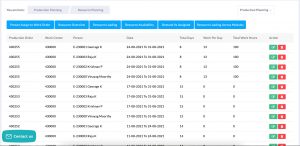

We can assign resources to a production order automatically. We will use the Work Center and its resource assignment for this purpose.

Users can continually readjust the automatic assignment based on the business scenario. This action will result in Production orders appearing in the individual employee’s Time sheets.

Users can enter the actual hours worked on a production order to precisely calculate the resource costs.

The resource costs will appear in the production order confirmation screen. OneBusiness Production planning has a facility to deactivate the resource planning for a production order completely.

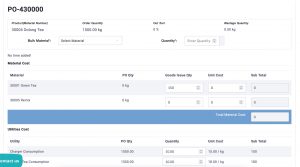

Cost Planning

Even though it is an optional step there are numerous advantages in doing this transaction. It gives an opportunity to compare the plan and actual costs of a production order. OneBusiness ERP production planning is an easy tool for cost planning. The learning of the deviations during the production order processing will improve the operational efficiency.

Material Reservation

The production planning process will create reservations if the raw material is in stock. Else, it will create a purchase requisition. Therefore, it is always good to keep the raw material in stock for a definite period.